Asbestos Abatement at Power Generating Facilities Throughout Canada and South America

National Reach With a Local Touch

Enviro-Vac® a Trusted Leader in Power Plant Decontamination

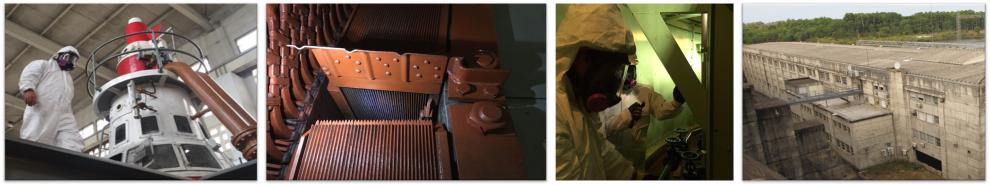

Enviro-Vac is acknowledged as a leading provider of specialized decontamination and asbestos abatement solutions for power generation facilities. These asbestos removal projects frequently occur in hazardous, challenging, and sensitive environments. The company's abatement technicians demonstrate advanced expertise in electrical safety protocols, and a substantial portion of work within power generation settings is conducted on a continual basis for both national and international clients.

Case Study

Asbestos Contamination in a Latin American Power Plant

A major electrical power facility in Latin America identified extensive asbestos contamination resulting from the use of asbestos-containing materials within its machinery and infrastructure. To ensure worker safety during equipment servicing and replacement, comprehensive abatement and decontamination efforts were mandated prior to initiating any maintenance activities. A primary challenge involved maintaining continuous plant operations throughout the remediation process, as the facility supplies electricity to thousands of customers and institutions. Addressing this issue required an experienced abatement team proficient in operating safely within high-voltage environments and capable of executing rigorous remediation schedules in accordance with a detailed abatement plan.

The Solution

Enviro-Vac was engaged for this project due to the specialized training and certifications held by its personnel in safely working around energized electrical systems. The qualified abatement team possesd the necessary clearances to access and perform tasks in close proximity to high-voltage components.

The asbestos abatement process was executed in a cost-efficient manner by deploying multiple specialized crews from Canada, ensuring an elevated level of expertise throughout the project. Comprehensive adherence to health and safety standards was maintained, allowing the project to be completed within the planned 16-week timeframe. Enviro-Vac has an established track record, having successfully completed numerous energized abatement projects across Canada and Latin America without any reported safety incidents during operations near energized equipment.

Industry Trade Challenge

Enviro-Vac excels in addressing one of the industry's key challenges: the retention of abatement personnel cross-trained in working near high-voltage environments, certifications for asbestos and lead management, and expertise in complex tasks such as stator removal and media blasting under controlled conditions.

The operational requirements of generating stations and power sector clients frequently differ from those found in other industries, though some obstacles may be comparable. Enviro-Vac’s team of highly trained specialists delivers comprehensive asbestos abatement and decontamination services within active and sensitive facilities, ensuring these processes are conducted with minimal disruption to standard plant operations.

Summary of Enviro-Vac's Approach

Enviro-Vac offers comprehensive turn-key solutions. Stringent health and safety protocols are integrated throughout each phase of the project, from pre-job planning through execution and debriefing. The company adheres to all relevant regulatory requirements to uphold performance standards and foster continual improvement.

Regular project meetings are held with client consultants, health and safety professionals, and key stakeholders to review work procedures, discuss scope modifications, and assess progress.

Each project commences with a thorough risk assessment and the preparation of a detailed methodology statement outlining safe work practices. These documents are submitted to regulatory authorities via a Notice of Project (NOP) prior to commencement and are supported by ongoing onsite audit processes.